Home / Drug discovery / Chemistry / Synthetic chemistry

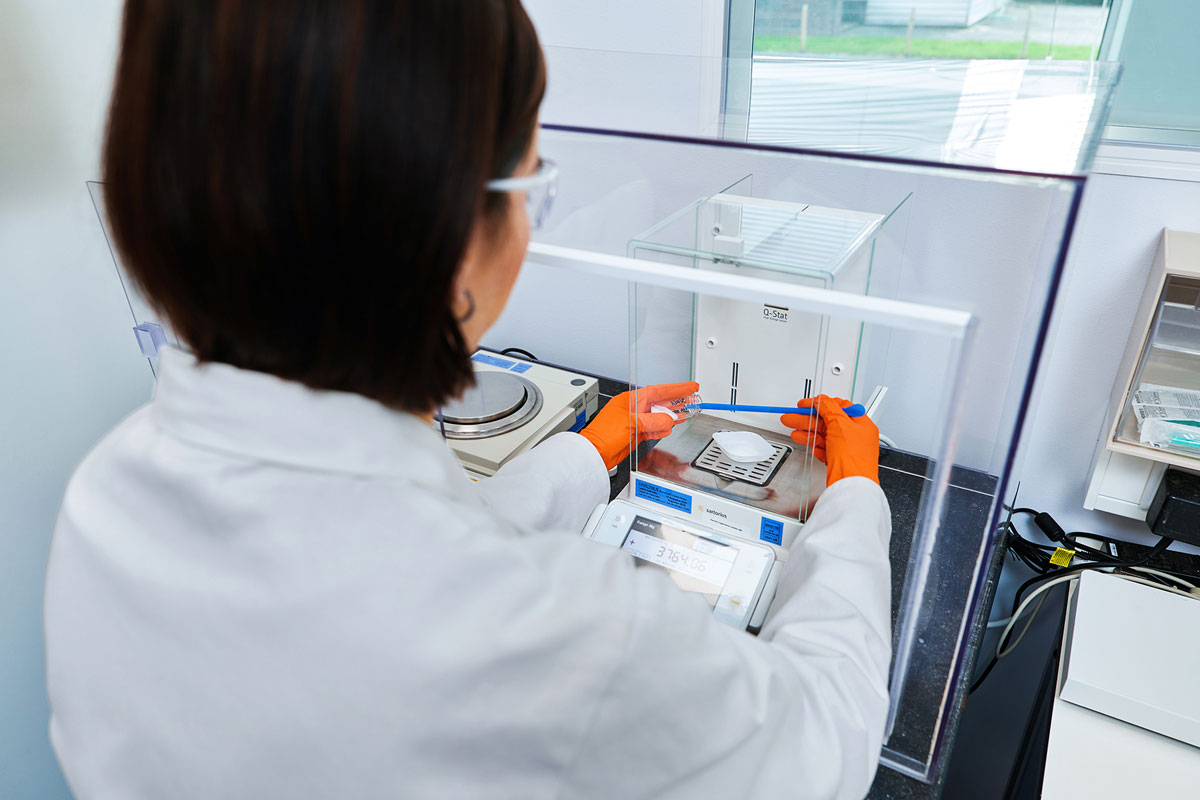

Synthetic chemistry drug discovery services

Our synthetic chemistry services help you move faster from design to delivery across a broad range of modalities, from small molecules to highly potent payloads.

As a CRO specializing in drug discovery chemistry, we create efficient synthetic routes, custom compounds and scalable intermediates reliably. Our chemists work as an extension of your team, providing strategic input on route design and synthetic planning for biotechs and virtual companies. By coordinating closely with process and formulation chemists, we ensure smooth transfer beyond discovery. By combining synthetic and computational chemistry expertise, we deliver reproducible quality, reliable timelines, and confident progress toward your next milestone.

Capabilities include:

- Custom synthesis – Defined compounds, including complex heteroaromatics and functionalized scaffolds

- Building blocks and intermediates – Preparation of key synthetic intermediates for medicinal chemistry and development teams.

- Chiral and isotopic compounds – Synthesis of enantiopure and labeled molecules.

Related services

Connected chemistry expertise

Our synthetic chemistry services link directly with our medicinal and computational chemistry to support better design and faster candidate optimization.

From SAR analysis to structure-based modeling and advanced specialty chemistry – photochemistry, flow, biocatalysis, and isotope labeling – you get consistent data, coordinated workflows and reliable handover into development.

What do our partners say?

“The team is making short work of these targets, so we will have to start thinking of some additional targets!”

Director

Biotech

“Through our dedicated FTE resource at Symeres we have achieved remarkable results, not only by developing a new “aspirational” synthetic route but also by significantly improving the current one to deliver a sustainable route for commercial production and giving us two options for late development.”

Associate Director

Large pharma, Europe

“A sign that things are going well - we keep coming to you. We’ve given Symeres five or six different projects already. That’s almost unheard of for us.“

Senior Director, Manufacturing

Top 10 global pharma

“The progression was really phenomenal. I am truly impressed. There is a world of difference between you and other CROs.”

Start-up Founder

Biotech

“We are developing the most complex molecule that is built at this time in the world…We work with a lot of CROs, also chemistry CROs, and so far Symeres has done the best job with respect to transparency and also to troubleshoot the problems and find a solution. Over the years we have been really impressed with the work that Symeres has done.”

Founder

Biotech

“If the compound can be made, Symeres will undoubtedly find out a good way to make it.”

Dooyoung Jung, CEO

Pinotbio

“They’ve always met or exceeded my expectations - that’s why I continue to come back, company after company, year after year.”

Allen Horhota, Vice-President Platform & Delivery

Seamless Therapeutics

“I would like to extend my thanks for the excellent work Symeres has done in synthesizing the API for Part 1 of our project. Your communication throughout the process was outstanding, and the sense of urgency with which you operated allowed us to complete this phase promptly and efficiently.”

Leader

Large biotech

“We’ve been with them…over 10 years. The cost, the flexibility - the value is just so strong. That’s why we’ve stuck with them.”

Senior Director, CMC

Biotech

Your discovery and development partner

Symeres supports small-molecule programs from discovery through IND with openness, agility and scientific depth.

Our connected teams in Europe and North America share data transparently, adapt quickly to new results, and stay accountable from first experiments to IND, to keep your progress clear, connected and continuous.

Resources we think you'll love

Blog

When a clean PK profile is actually a warning sign

Blog

CDMO red flags you can’t ignore: Communication breakdowns

Blog

CDMO red flags you can’t ignore: Capacity constraints and resource stretch

Blog

CDMO red flags you can’t ignore: Regulatory shortfalls and misalignment

Whitepaper

5 CDMO red flags you can’t ignore: A guide for biotechs and pharma

Blog

CDMO red flags you can’t ignore: Underestimating technology transfer complexity

Blog

O.N.E Symeres: A practical approach to real-world drug development

Blog

CDMO red flags you can’t ignore: Undefined or shifting project scope

Whitepaper

Accelerating chemical innovation: Unveiling Symeres’ parallel chemistry

Webinar | On-demand

From racemic to pure the art and science of enantiomer separation

Whitepaper

IND & IMPD enabling developability roadmap

Whitepaper

Innovations in unnatural amino acids: Advancing functional diversity and applications

Whitepaper

Leveraging copper-catalyzed ullmann-type cross-coupling reactions in PR&D

Whitepaper

Managing nitrosamines in the pharmaceutical industry: A comprehensive approach

Whitepaper

Optimizing solid-state properties and enhancing API bioavailability through physicochemical prediction

Whitepaper

Stable isotope-labeled compounds

Whitepaper

Unlocking the potential of high-throughput screening: Symegold library design and expansion insights

Interviews

Insights into drug discovery and development 2025

Interviews

Interview with the computer-aided drug design (CADD) department

Interviews

Meet the Organix Director, Mario Gonzalez

Interviews

Interview with the new Managing Director of Symeres Groningen

Interviews

An interview with Yadan Chen and Paul O’Shea

Interviews

An interview with Anu Mahadevan and Paul Blundell

Blog

Crystalline and liquid crystalline 25-hydroxy-cholest-5-en-3-sulfate sodium and methods for preparing same

Webinar | On-demand

In vivo pharmacokinetic experiments in preclinical drug development

Webinar | On-demand

Accelerating medicinal chemistry by rapid analoging

Webinar | On-demand

Solid-state chemistry part II: Optimal form selection by controlled crystallization

Webinar | On-demand

Route scouting for kilogram-scale manufacturing of APIs

Webinar | On-demand

Solid-state chemistry part I: Introduction

Synthetic chemistry success stories

Our chemistry teams routinely deliver custom syntheses, parallel libraries, and complex routes for both biotech and pharma programs. These projects have supported early discovery, candidate optimization, and preparation for IND.

Speak with our synthetic chemistry experts

Let us support the discovery and development of your next breakthrough.