Over 50% of current drugs in development are chiral. At Symeres we apply a suite of state-of-the-art technologies to obtain the desired chiral compound in high enantiomeric purity. For decades, Symeres has been supporting the global pharma and biotech industry with the synthesis and delivery of chiral compounds, both through synthesis and purification strategies.

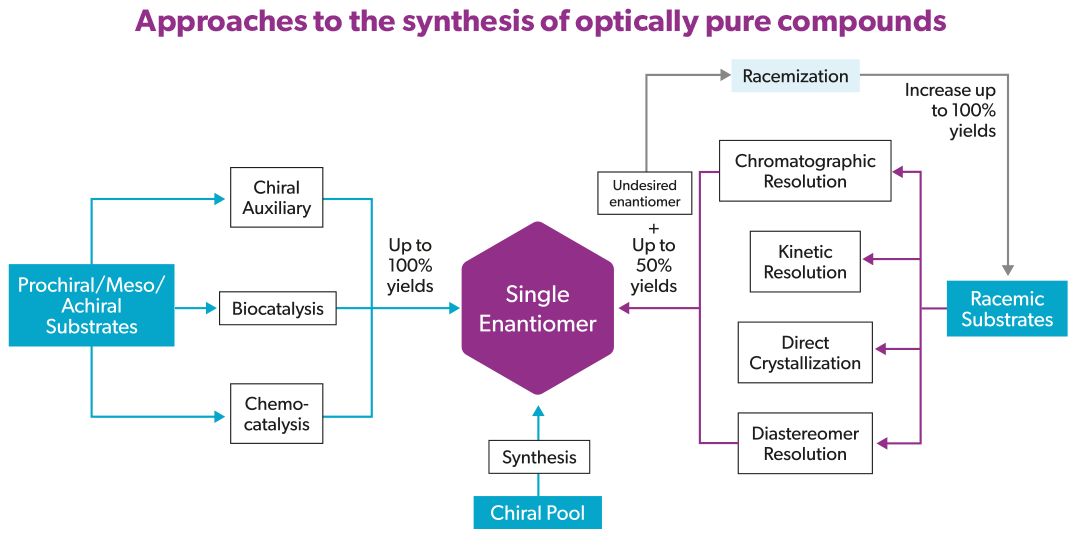

Chiral Supercritical Fluid Chromatography (SFC) is often the method of choice for a quick delivery of ~100g quantities of the single enantiomer in pre-clinical drug R&D. Resolution techniques (right side of the scheme below), although fast and reliable, have a maximum of 50% theoretical yield. However, by applying racemization conditions, e.g. mild basic conditions or establishing retro-synthetic equilibria, one can turn the already known resolution method into a 100% theoretical yield (better economics, less waste). As a further improvement on this, Symeres often applies the racemization in the same pot (DKR type of processing: CIDT – Crystallization-Induced Diastereomeric Transformation), or even without a chiral resolving agent by conglomerate crystallization behavior (e.g. Viedma Ripening or TCID – Temperature Cycling Induced Deracemization).

Alternatively, the desired single enantiomer compound can be obtained efficiently by chiral pool synthesis or via asymmetric synthesis using a prochiral starting material. Chiral catalysis methods (bio- and chemo-catalysis) are often applied in later stages of the drug development trajectory, when slightly longer timelines allow for route scouting and process development and cost of goods come into play. Symeres has in-house bio- and chemo-catalysis expert teams developing scalable chiral catalytic processes to deliver the single enantiomer. For example, we use commercially available ketoreductases, transaminases, imine reductases, and chiral Ru-complexes, respectively.

For all chiral technologies, Symeres has the experience to deliver the single enantiomer of choice in high purity and on time.