The ‘Computer-Aided Drug Design’ Department provides computational design support for our clients’ drug discovery projects. In this interview, we introduce our CADD experts and see what exciting developments are awaiting us this year.

Can you introduce yourselves?

Eddy Damen did his PhD in Nijmegen and started as an organic chemist in Nijmegen 24 years ago. After being involved in building the Parallel Chemistry Department in the early 2000s, Eddy changed departments in around 2012, when Mercachem began offering medicinal chemistry services, including computational chemistry. Eddy started CADD support by learning on the job.

In 2021, Giovanni Bolcato joined the team. He studied medicinal chemistry and pharmaceutical technologies and did his PhD in pharmaceutical sciences, working in the field of computational chemistry. He worked with a group in Sweden, on a project about the application and development of artificial intelligence (AI) methods in drug discovery before joining Symeres.

Can you explain what the CADD Department does?

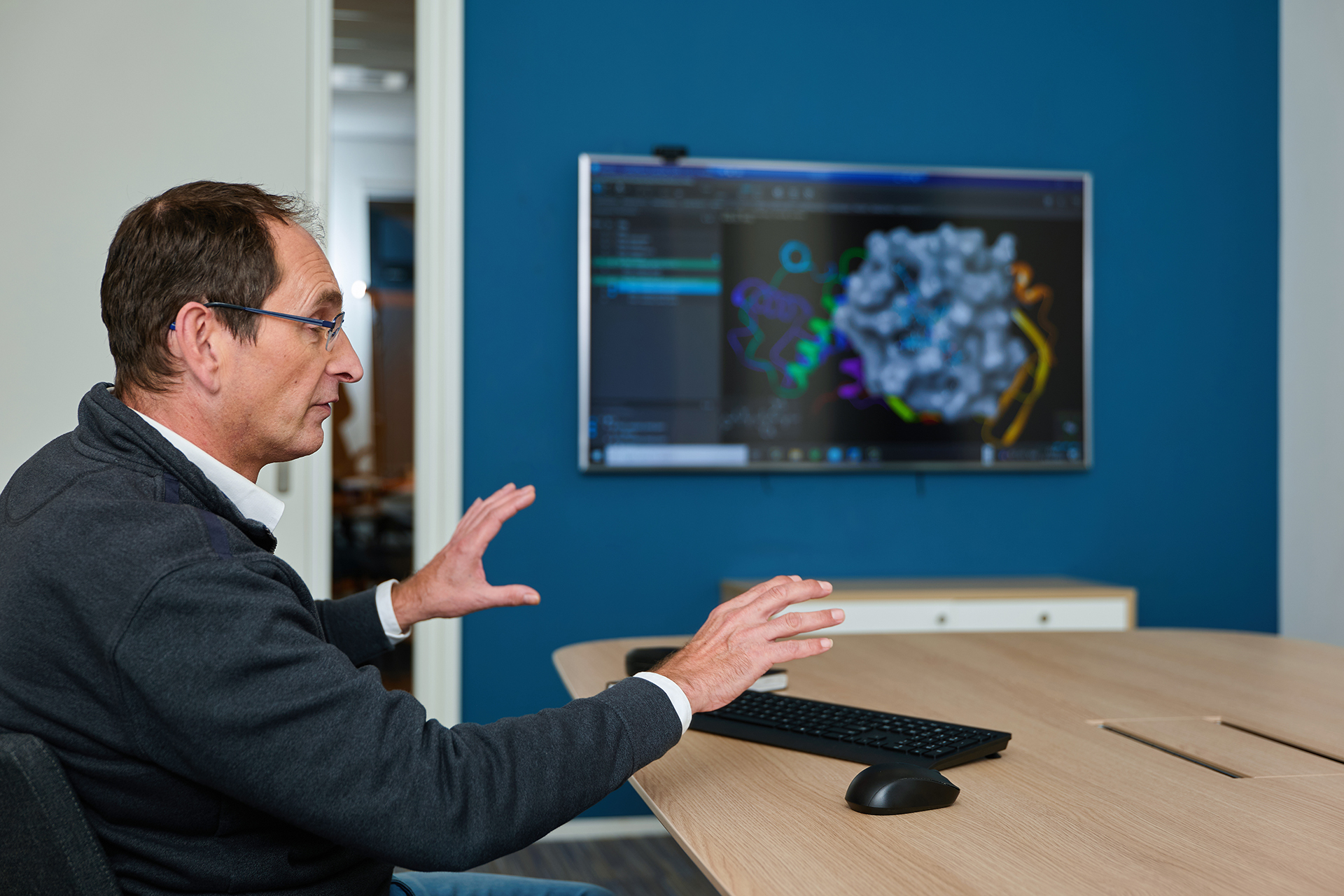

CADD can be divided into ligand- and structure-based methods. Structure-based design, where you design your compounds based on a protein or receptor you’re targeting, makes up the vast majority of daily work, since nowadays more and more 3D structural data, like crystal structures and (AI-derived) homology models, are available. With this structural information, the computer can help to find potentially active compounds. Often, the team members design and propose compounds that can be judged and prioritized by computational methods. Eddy commented: “CADD at Symeres is mainly about generating ideas and understanding which ideas will take the project in which direction.”

What software do you use?

At the moment, the CADD Department uses the software suites MOE, from the Chemical Computing Group, and Maestro, from Schrödinger. Furthermore, they have access to Spark (Cresset), which has been quite successful in several projects where scaffold hopping was requested. Finally, LiveDesign™ (Schrödinger) can be used to share project data and computational models. In this web-based application running from the Amazon cloud, users can, for example, dock their design ideas. Several team leaders of medicinal chemistry and one customer have access to LiveDesign™, facilitating design sessions by sharing ideas.

Can you highlight some of your recent work?

Next to assisting in a dozen projects using different computational approaches, the CADD team offers virtual screening. In virtual screening, a range of chemical structures are tested on the computer model of the intended target to see which structures theoretically would bind to the target. If this is done well, it can greatly reduce the number of compounds that need to be screened through an actual biochemical assay, saving the customer both time and money. For this, a complete workflow has been established, from selection and preparation of a database to screening and nomination of the final hits. At Symeres, virtual screening can be performed using either a database of 8.8 million stock compounds from a commercial supplier, the Symegold library (75,000 compounds) available at Axxam for high-throughput screening, or the Symeres Virtual Library. At the moment, this last library contains about 17 million compounds derived from unique scaffolds, which have been validated for library synthesis. Also, a diverse subset of the Enamine REAL™ library (31 million compounds) has been prepared and can be used off the shelf in virtual screening.

Both computational chemists emphasize that the virtual screening offered at Symeres is unique compared to the virtual screening at many other companies. “While most companies only return hits based on a particular scoring and ranking in silico, we at Symeres integrate a substantial amount of human intelligence, i.e., the outstanding knowledge of both our medicinal and synthetic chemists.”

Another recent highlight is the introduction of free-energy perturbation (FEP+). FEP+ is a computational method based on thermodynamics to calculate and predict the relative binding free energy of a ligand in a receptor. These calculations are computationally very demanding and have to be performed on a cluster of GPUs. When applied in the right way, FEP+ can positively contribute to lead-optimization projects by prioritizing compounds for syntheses.

Lately, a lot has been written about AI in different stages of medicinal chemistry projects. What is your opinion of AI and what are your future expectations?

Although worldwide billions and billions of dollars have been invested in AI, Giovanni and Eddy predict that eventually only a few companies introducing outstanding techniques will survive. “AI is dependent on ‘big data’ and performs best when the algorithms and models are fed with a very large amount of high-quality data,” says Giovanni. “However, this kind of data is only sporadically available in the public domain.”

Eddy adds, “This lack of data is especially true for compounds that enter clinical trials, and those compounds are the ones AI could learn the most from.” Nevertheless, machine learning will have its place in the toolbox and the next five years will be critical for its true value to be demonstrated.

We would like to thank Eddy and Giovanni for their contribution to this article. If you want to receive updates on their progress in 2024, follow us on LinkedIn or subscribe to our newsletter.

Please contact us via our contact form if you have a project that would benefit from these solutions.